Merry Christmas & Happy New Year!

Closed: December 23rd to January 1st

Closed: December 23rd to January 1st

Showing 1–16 of 271 resultsSorted by popularity

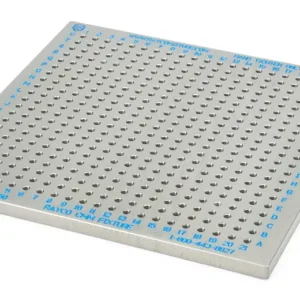

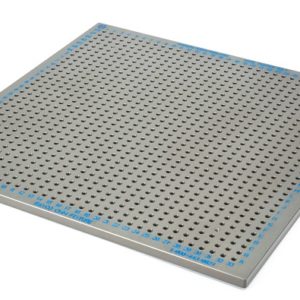

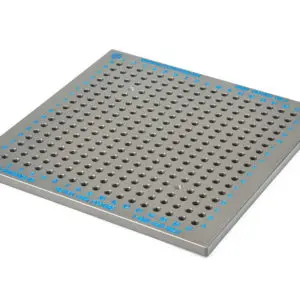

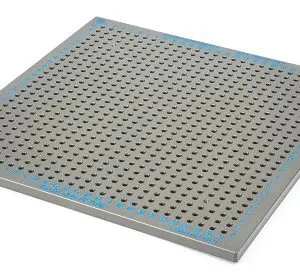

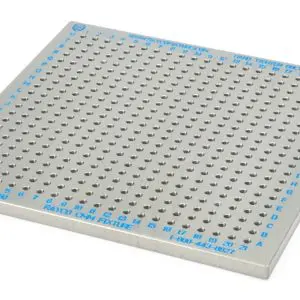

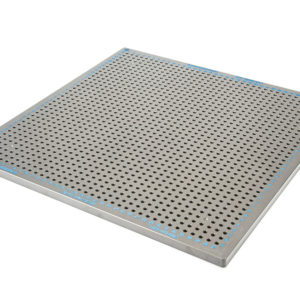

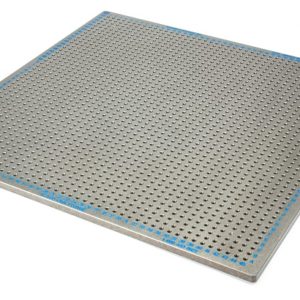

12” [X] x 12” [Y] x 0.50” with 1/4-20 threaded holes spaced 0.50” on centers

6” [X] x 6” [Y] x 0.375” with 1/4-20 threaded holes spaced 0.50” on centers

18” [X] x 18” [Y] x 0.50” with 1/4-20 threaded holes spaced 0.50” on centers

3” x 2” x 3.5” with 1/4-20 threaded holes.

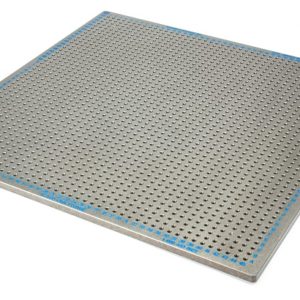

24” [X] x 24” [Y] x 0.50” with 1/4-20 threaded holes spaced 0.50” on centers

300mm [X] x 300mm [Y] x 13mm with M8 threaded holes spaced 15mm on centers

28” [X] x 40” [Y] x 0.75” with 1/4-20 threaded holes spaced 0.50” on centers

5” x 6” x 12” with 1/4-20 threaded holes spaced 0.50” on centers

15” [X] x 15” [Y] x 0.50” with 1/4-20 threaded holes spaced 0.50” on centers

600mm [X] x 600mm [Y] x 13mm with M6 threaded holes spaced 15mm on centers

300mm [X] x 300mm [Y] x 13mm with M6 threaded holes spaced 15mm on centers

600mm [X] x 600mm [Y] x 19mm with M8 threaded holes spaced 15mm on centers

2” sq. x 3” H with 1/4-20 threaded holes spaced 0.50” on centers

750mm [X] x 750mm [Y] x 19mm with M8 threaded holes spaced 15mm on centers

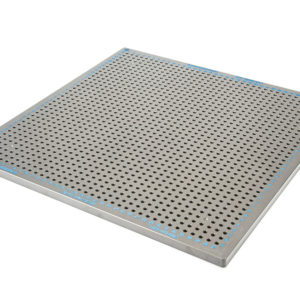

24” [X] x 24” [Y] x 0.75” with 1/4-20 threaded holes spaced 0.50” on centers

50mm Sq. Base x 75mm H with M8 threaded holes spaced 10mm on centers

RAYCO CMM Fixture Plates come in cast aluminum, steel, and acrylic.

Just select from our standard sizes or contact us to receive a custom size quote to your specific needs. Rayco does not charge extra to put mounting holes into any Rayco plate, just indicate if you would like mounting holes at time of order by specifying the make, model and size (x,y,z) of your machine. At Rayco we have a large database of CMM and Vision system mounting hole patterns and can assist you in selecting the proper size plate to fit your needs and your machines.

Please also remember that if you have a calibration sphere or probe rack that may interfere with the mounting position of your plate.

Can't find what you're looking for? Fill out our contact form or call us.