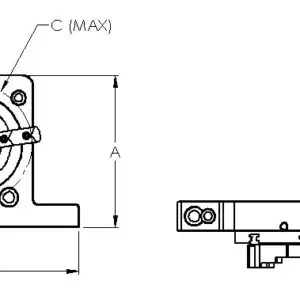

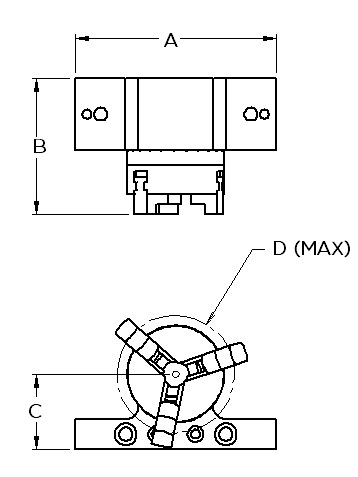

3 Jaw Chucks

Our 3 jaw chucks are lightweight, versatile, self-centering devices that easily and securely clamp round, hexagonal, or irregularly-shaped workpieces. We offer three standard options for CMMs and can manufacture custom chucks based on specific application requirements. We offer a 30-day return policy on all standard components.

Showing all 6 results