Customer Service: 800-443-8827 | SALES@RAYCOFIXTURE.COM

Merry Christmas & Happy New Year!

Closed: December 23rd to January 1st

Customer Service: 800-443-8827 | SALES@RAYCOFIXTURE.COM

Closed: December 23rd to January 1st

Showing all 9 resultsSorted by popularity

1/4-20 Threaded Vision Clamping Kit A with Total Component Count: 39

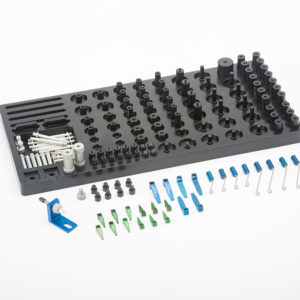

1/4-20 Threaded Vision Clamping Kit B with Total Component Count: 86

M4 Threaded Vision Clamping Kit A with Total Component Count: 39

M4 Threaded Vision Clamping Kit C with Total Component Count: 111

M4 Threaded Vision Clamping Kit B with Total Component Count: 86

M6 Threaded Vision Clamping Kit C with Total Component Count: 111

M6 Threaded Vision Clamping Kit B with Total Component Count: 86

M6 Threaded Vision Clamping Kit A with Total Component Count: 39

1/4-20 Threaded Vision Clamping Kit C with Total Component Count: 111