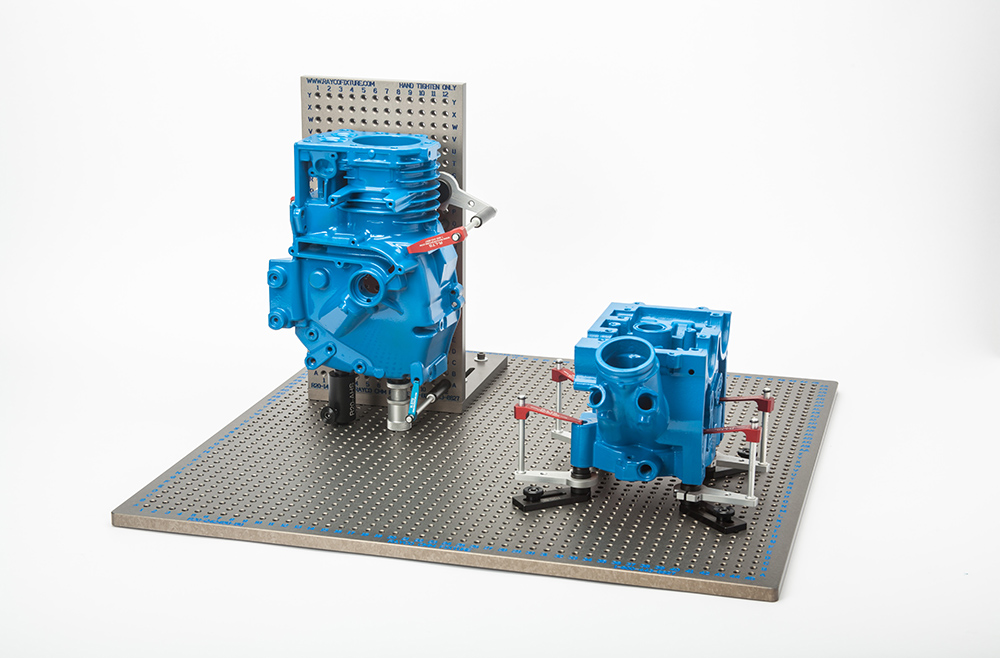

CMM fixture plates and other components help improve repeatability, increase accuracy, and reduce costs in manufacturing processes.

Continue reading to learn about fixture plates and other versatile components that can decrease your bottom line and produce consistently better products.

What Are CMM Fixture Plates?

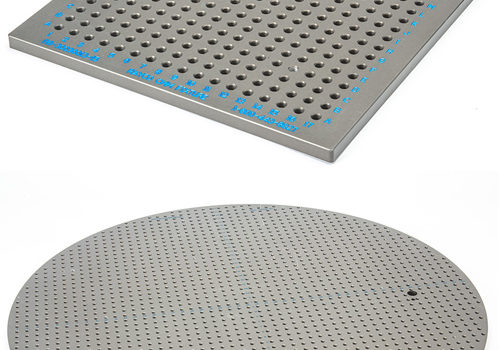

A CMM fixture plate is typically a square or rectangular metal plate used to protect the surface of the CMM machine. It also has threaded holes throughout the plate in a grid pattern with numbers and letters in the x and y axis. Its purpose is to support the quality departments operations with greater repeatability, interchangeability, and dependability of finished products.

Aluminum and steel fixture plates reduce production times by accommodating faster set-ups and by streamlining repeatability. Fixtures also decrease the need for unreliable and outdated fixturing options, such as glue and tape.

They also help to reduce skill requirements for operators by simplifying workpiece mounting processes and improving conformity through production runs.

Types of Components

There are various types of fixture plate components used in quality applications, including:

- Standoffs

- Vertical Plates

- Vacuum Components

- Locating Components

- Clamps & Other Holding Components

Let’s examine each type of tooling component to better understand their purpose and benefits.

Standoffs

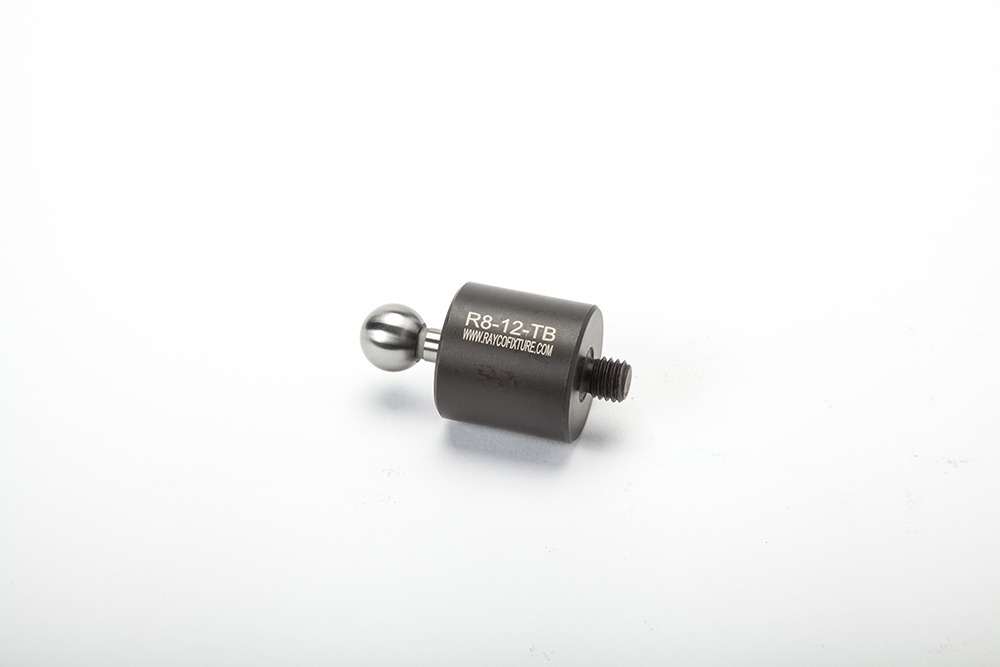

The use of standoffs in a quality setup lifts products off the fixture plate, no matter the weight, and with the help of components when necessary. However, standard standoffs are threaded with male and female threads, allowing them to be screwed into the fixture plates and stacked on top of each other if needed. Types of standoffs include pin, magnetic, rotating, spring-loaded, standard, and with a tooling ball.

Vertical Plates

A vertical plate, sometimes referred to as a fixture plate, is simply a metal plate set at 90 degrees with threaded holes spaced on center and engraved number in the x-axis and letters in the y-axis. Vertical plates are mounted on fixture plates to create a vertical extension of the plate, and are available with an array of sizes to support precise component positioning and repeatability. Attaching and detaching components is fast and easy, allowing you to adapt to any application, no matter the part size.

Vacuum Components

Vacuum components safely, but firmly, affix parts in place. These parts range from vacuum hoses to suction cups to various vacuum pump assemblies. These vacuum-assisted components improve setup repeatability and are suitable for multi-component machining setups.

Locating Components

Locating components, which are commonly called locating devices, are components that maintain a precise position that may be difficult to achieve during setup. It’s imperative that the workpiece is affixed and immobile during machining to ensure precision. You may select between pin and button, cylindrical, conical profile, and rest pin options.

Clamps/Holding

As the name suggests, clamping and holding components securely hold parts in perfect positions for machining. These components range from male centers to spring-holding devices to tension springs, each type providing a unique holding ability.

Get Custom Fixtures & Components From Rayco

Rayco Fixture is a leading manufacturer of modular tooling plate fixtures and components for CMMs. When you turn to us for your CMM fixture plates and components, know that we always customize them to meet your unique needs. If you need help selecting the right components or want to design a custom fixture, contact us today.