Spring holding devices are springs that store energy while in a compressed state or when force is applied and held. Once the force is removed, the spring returns to its original, uncoiled state. You can find spring-holding devices in many consumer, commercial, and industrial applications, products, and systems.

There are three primary categories of spring holding devices: loaded pusher clamps, locating pin standoffs, and rotational spring locating pin standoffs. Choosing between them comes down to understanding what they do, how they work, and the unique requirements of your application.

This brief guide will detail all three categories and how to select the best one for your application.

Spring-Loaded Pusher Clamp

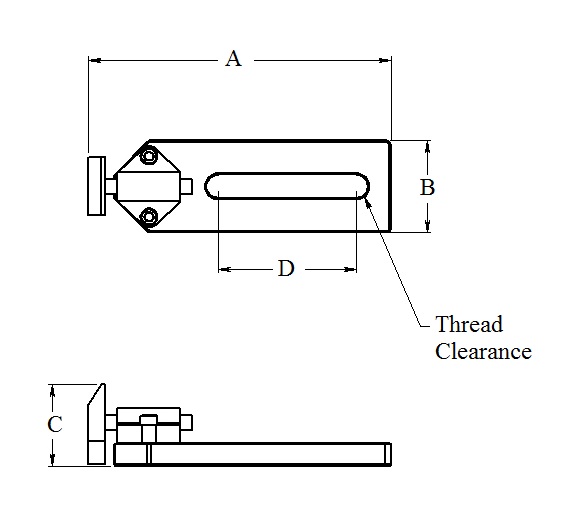

A spring-loaded pusher clamp secures parts, materials, and objects in place. Thanks to their ability to prevent parts from sliding or moving during inspection, they are an essential part of any. A spring-loaded hold-down pusher clamp operates similarly to other clamps, except that it pushes/positions parts against a vertical surface, wall, or corner.

Rayco offers a spring-loaded pusher clamp, the R20-SLPC. The clamp comes with a thumb screw. It’s ideal for coordinate measuring machines (CMMs), shop-floor gauging systems, multi-sensor machines, and other quality control applications.

Spring Locating Pin Standoff

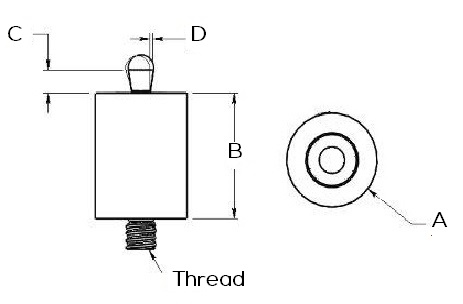

A spring locating pin standoff is the ideal mechanism for mitigating human and part-locating errors when positioning components on fixture setups. When positioning a part against a spring locating pin standoff, the locating pin provides enough resistance to side force to indicate if the part is not ideally positioned or held in place.

Rayco’s R20-751-SPS is an example of a spring locating pin standoff. It’s available in many sizes and thread types, including M4, M6, M8, and ¼-20. The R20-751-SPS standoff works by sliding a part into place. Once the part is in place, the side force is reduced, and the locating pin returns to its upright position. This simple mechanism ensures correct positioning and contact for parts once clamped.

Rotational Spring Locating Pin Standoff

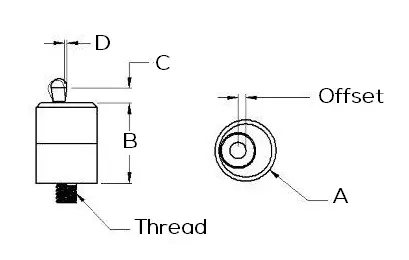

You can position multiple rotational spring locating pin standoffs, like Rayco’s R4-19-CSPS, around the perimeter of a single plate or fixture to position components with multiple surfaces and geometries. This type of holding device ensures proper alignment before you clamp the part in place.

Find the Right Spring Holding Device Today

Do you need help selecting the best spring holding device? Contact Rayco today. For over 40 years, we’ve designed and manufactured innovative custom fixture kits, components, and spring-loaded devices. Our expert team can help you find what you need!