Rayco Fixture has been a trusted name in the quality industry for more than four decades. We sell fixture plates for CMMs or work surfaces, including the option of a portable metrology table for FARO Arms or 3D laser scanners. Our top priority is helping you decrease inspection times, enhance repeatability, and easily manage high-volume projects.

Keep reading to learn more about what fixture plates are and how they can help you.

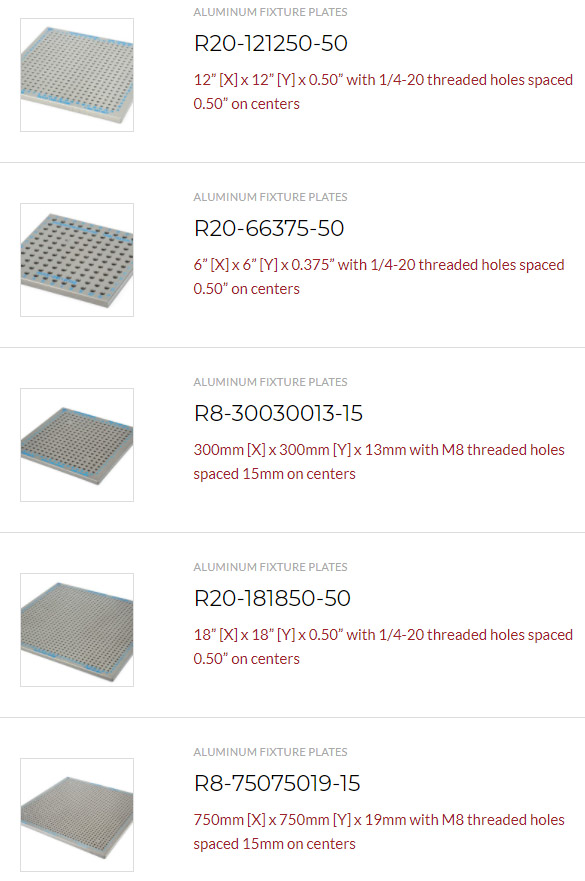

Aluminum Fixture Plates Offered by Rayco

Rayco’s CMM aluminum fixtures improve the preciseness, duplicability, and throughput of your inspection process, providing fast, reproducible set-ups.

Our hard-coat-anodized aluminum plates are the most durable and cost-effective on the market. No matter the machine type or application, we can find the right plate for you. Our tooling plates are currently available in rectangular, square, and round shapes, with your choice of 1/4-20, M6, or M8 thread type with custom threads available upon request.

We also offer a range of aluminum plates and options to suit your exact needs. You can view some of our options below, or view our complete inventory here. If you don’t see what you need here on the website, don’t hesitate to contact us.

Whether you are perfecting components for aerospace, automobile manufacturing, CMM machining, or food production, Rayco Fixture offers a complete range of custom-produced products to suit your specific needs.

Aluminum Fixture Plate Applications

Rayco Fixture provides high-quality aluminum plates that are perfect for any industry and CMM application. Our precise, quality products help remove variation from inspection, thus enhancing reproducibility and precision. Additionally, our tooling plates are perfect for a wide array of industry applications, including:

Automotive

At Rayco, we know that the automotive industry relies on precision. From component measurements to quality control, our CMM plates will help you drive manufacturing efficiency from start to finish.

Medical

Enhance your quality applications with our custom fixture plates. We offer custom aluminum plates that can be integrated into your existing CMM machine and romer arm system, as well as an optional meteorology table that can be added onto any size fixture plate.

Aerospace

Rayco’s fixture plates help aerospace manufacturers achieve repeatable, efficient, traceable results that exceed the most exacting tolerance specifications, allowing large parts to be measured on any size CMM.

Factors to Consider When Selecting a Fixture Plate

There are several key factors to consider when choosing a tooling plate, chief among them being the desired application.

Does your application heavily rely on dimensional control? Are precision and dimensional stability important?

Next, you must also consider how the plate will be mounted (horizontally, vertically, etc.).

Lastly, you also need to think about the fasteners you are using (their nominal diameter and their threads per inch or millimeter). We can customize our fixtures based on inch and metric thread sizes; as previously mentioned, we offer ¼-20-inch thread types, as well as M4, M6, and M8 metric thread types.

If you still have questions, contact us today. We’re happy to help you find the best aluminum tooling plate for your needs—we can even provide guidance through visual designs.

Steel Versus Aluminum Fixture Plates

Rayco sells both aluminum and steel fixture plates. You may be wondering which material is best for your needs. Take a look at our list of pros and cons below:

Steel

- Durable: Steel is typically more durable than aluminum. You will notice less damage or threading wear with steel.

- Weight: Heavier than aluminum, which helps keep a fixed position.

- More Expensive: Due to its durability and strength, steel tends to have higher upfront costs.

Aluminum

- Cost-Effective: Manufacturers looking to spend less money will want to choose aluminum.

- Lighter: Aluminum is a lightweight material and easier to move around.

- Corrosion Resistance: Aluminum is usually more prone to corrosion when compared to steel. However, Rayco offers hard-anodized aluminum fixtures. Hard-anodized means that our aluminum goes through an electrolytic process. In this process, an electrical current causes oxide, which then hardens on the aluminum and makes it more resistant to corrosion. This type of aluminum is very corrosion-resistant and great for electronic equipment manufacturing applications.

As we mentioned earlier, knowing what type of application you need a fixture plate for is the first step in choosing the right type. Both materials have their advantages and disadvantages. Please contact Rayco today with any questions, and we’ll get back to you as soon as possible.

Request a Quote Today

For more than 44 years, Rayco Fixture has served as an industry-leading supplier of high-quality steel and aluminum tooling plates. Our in-house design experts can expertly manage all your fixturing needs. Whether you need a CMM fixturing kits or custom fixtures to improve quality processes, we’re here to help. Contact our team today with your questions or to request a hassle-free quote.