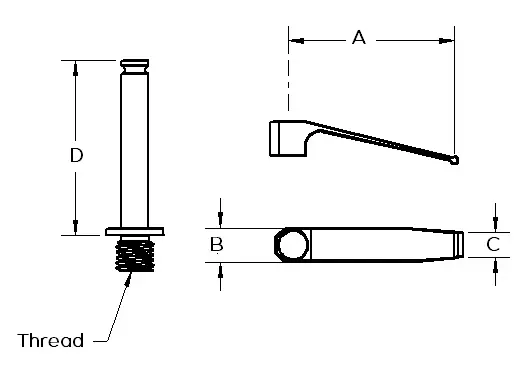

Much like the name implies, tension springs, sometimes called hold down arms, are aluminum arms that hold tension onto parts with little pressure. They are made from aluminum and have optional rubber tips or plungers available along with two post height options.

These small but critical parts are ideally suited to positioning components during inspections, allowing for quick release after inspection, and maintaining and releasing tension. Tension springs can be used in various inspection industries from automotive, aerospace, defense, medical and manufacturing inspection.

How Tension Springs Work

The amount of tension within the springs is determined by the given application, which in turn defines the size of arm used and how much pressure is applied to the arm. In essence, tension springs work by storing tension or energy.

If pressure is applied to the tension spring, the spring will flex holding the part in a fixed position. However, once the arm is removed, the tension spring arm will go back to its original shape.

Benefits

There are several immediate benefits to using spring tension clamps.

First, tension springs are versatile and available in many sizes. They’re also strong, tough, and durable, making them exceptionally well-suited for applications where they may be exposed to extreme cold, high heat, chemicals, or corrosive conditions.

Tensioning springs are also energy-efficient solutions that store energy in their original state and release it once a load is removed. This is essential for constant and repeatable cycling equipment and machinery.

Lastly, tension springs come with many options, such as rubber tipped, plunger, mini, small, and XL for various quality control and inspection across many industries.

How to Select the Right Tension Spring

Selecting the proper tension spring comes down to your specific application. The spring’s size, post height, rubber tipped, and plunger are primarily driven by the spring’s purpose, and the physical space the tension spring occupies. Other accessories are available that work with our tension springs, such as tension spring brackets or slide bases.

The top four questions you need to ask before you purchase a tension spring are:

- Will the tension spring be holding a delicate part?

- How large or small is the part that needs to be held?

- What operating and environmental conditions will the spring be exposed to?

- Will you require other components to set up the part (standoffs, etc.)?

Rayco’s Solutions

For over 45 years, Rayco has developed an unsurpassed reputation as an innovator, market leader, and trusted partner for companies needing well-designed and well-manufactured fixture plates and components for CMM and vision machine applications.

We offer a wide range of standard and custom-engineered clamping and holding tension springs for multiple functions, envelopes, and requirements. Thread type options include ¼-20, M4, M6, and M8; the diameters available are 0.75 inches (19 millimeters) and one inch (25 millimeters). All standard components come with a 30-day return policy.

If you require a custom product, know that our engineers will guide you through the process every step of the way.

Purchase Tension Springs Today

Work with Rayco and get the quality you deserve! Contact us today to learn more about our tension springs or to start your custom design.