Merry Christmas & Happy New Year!

Closed: December 23rd to January 1st

Closed: December 23rd to January 1st

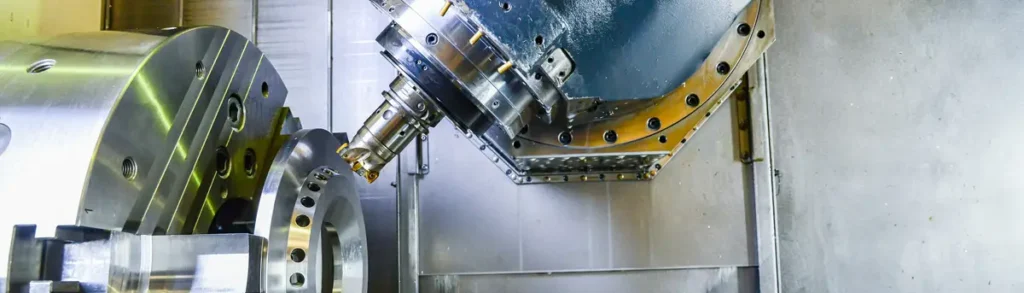

Fixture clamps may come in different styles and configurations, but they all serve one purpose: to hold workpieces securely. They’re used in many industries to help ensure precision during visual inspections, CMM inspections, and quality control processes.

Clamps come in a variety of designs, but they’re primarily classified by how they operate. The major categories are manual, screw-operated, pneumatic, spring-loaded, hydraulic, magnetic, vacuum, and wedge.

These refer to any fixture clamps that must be manually operated by a human. They don’t offer as much strength and clamping force as hydraulic and magnetic, but they also don’t require external power and are easier to maintain. Manual clamps come in a variety of configurations, including hold-down, where parts are secured from above and “held down,” and cross-hair arms, which provide adjustable clamping from multiple angles.

A fixture that has threaded mechanisms is considered screw-operated. One of the most common types of screw-operated fixture clamps is a 3-jaw chuck, which uses threaded mechanisms to close three jaws around cylindrical or hexagonal parts.

As the name suggests, pneumatic clamps are actuated by air. While not as powerful as hydraulic, they can still clamp with moderate to high force, and are typically preferred (along with hydraulic) for automated inspections. They provide the most consistent force because they don’t require human intervention, but they do need compressed air systems. A pusher clamp is a good example of a pneumatic fixture because it uses compressed air to push parts against stops or into position.

A spring-loaded clamp, like wire arms, features compressed or extended springs that help maintain constant pressure against workpieces. The biggest benefit is that the spring mechanism within the clamp automatically adjusts to accommodate minor variations in part thickness, ensuring accuracy. The spring mechanism also prevents excessive clamping that could deform thin-walled or delicate components.

Hydraulic clamps provide the highest, most consistent clamping force, making them ideal for heavy-duty or larger items. Like pneumatic, they are easy to automate, but require hydraulic power units and have high maintenance requirements. They’re also not ideal for any inspections that take place in a cleanroom because the hydraulic fluid needed to make the clamps work can become contaminated.

Magnetic fixture clamps are commonly used to hold ferrous materials from multiple angles. They can accommodate different part sizes without extensive reconfiguration, provide a distributed holding force to prevent damage on delicate parts, and offer better part access for complex components. Another significant benefit is that they eliminate threading, clamping, or mechanical adjustments—parts can be secured immediately just by coming into contact with the clamp. The downsides are that they only work on ferromagnetic materials, and curved surfaces will affect the clamping force.

Vacuum clamps are suction-based and used to hold components made from non-porous materials, including aluminum, plastics, composites, and ceramics. Like magnetic fixtures, vacuum fixtures provide a distributed clamping force, which makes them particularly good for delicate, thin, or flexible parts. They also minimize surface defects because they don’t require mechanical contact with the component and they can hold multiple small parts simultaneously to improve productivity.

Wedge clamps are typically only used in progressive die applications. This type of clamp is “wedged” between two surfaces. The angle of the wedge clamp determines the amount of force it will produce. They’re self-locking, require less vertical space than other clamping designs, and can be operated manually, pneumatically, or hydraulically, if needed.

Specialty clamps are application-specific and don’t necessarily fit perfectly into any of the above categories. There are too many types of specialty clamps to name, but a few include edge clamps, which grip part edges, toe clamps, which secure items from underneath, and V-clamps, which grip cylindrical-shaped parts like pipes.

Rayco Fixture manufactures standard and custom mechanical, vacuum, hydraulic, and magnetic fixtures and modular fixture plates for visual and CMM inspection applications. All components are made in-house in our U.S.-based facility.

Visit our website to learn more about our products or check out our blog for more resources.