A standoff is a type of fastener that creates gaps between two objects. They’re often used in computer assembly to ensure proper airflow between components, which keeps systems from overheating while in use. They’re also used to improve the stability of assembled structures because they help to reduce vibration and prevent unwanted movement.

Common Applications

As mentioned earlier, standoff fasteners are primarily used in electronics manufacturing to reduce electromagnetic interference. Other applications include:

- Industrial Control Panels: Standoffs can be used to secure, separate, and properly align electrical components in a control panel to prevent short circuits.

- Medical: They can also be used to mount printed circuit boards and screens without the risk of breaking compliance with strict hygiene standards.

- Telecommunications: Standoff fasteners are also used to mount components in telecommunications equipment, such as server racks and routers.

Types of Standoffs

Standoffs are available in a wide range of sizes and materials, including nylon, brass, and aluminum. There are also six primary types of standoff fasteners: pin, rotating, rounded, spring-loaded, tapered, and tooling ball.

Pin

Sometimes called male-female standoffs, pin standoffs are considered “traditional” standoffs. They feature two threaded sections—one with external (male) threads and the other with internal (female) threads. The male end is inserted into a pre-drilled hole while the female end secures the object. A pin standoff serves the same purpose as any standoff, which is to separate two objects.

Rotating

As the name suggests, a swivel spacer, or rotating standoff, uses rotational movement to separate two objects. They’re typically more flexible than standard spacers because of their swivel mechanism. The swivel mechanism usually is made from a ball bearing and is located between the internal and external threads. They’re used for applications that require better flexibility and adjustment since rotating standoffs can accommodate any movement or misalignment between components while still securely spacing them.

Rounded

Traditional standoffs are generally cylindrical or hexagonal. Rounded standoffs are unique because they are curved. They are generally used in situations where user safety might be important, as traditional standoffs can have sharp edges while rounded ones do not. They’re also ideal for fragile, easily damaged objects, as they can distribute pressure more evenly.

Spring-Loaded

Spring standoffs feature a built-in spring mechanism providing more flexibility and dynamic movement than traditional standoffs. Similar to the rotating standoff, the spring mechanism is located between the internal and external threads. They’re generally used in applications where height variations, vibration, and misalignment are issues.

Tapered

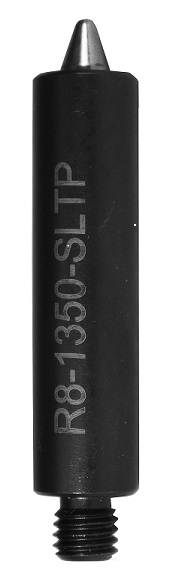

Tapered standoffs are identified by their conical shape (see image in previous section). When compared to other types of standoffs, tapered standoffs are better for applications where precision alignment is needed (e.g., centering components during assembly). They may also be used in applications where even load distribution is necessary to reduce stress and damage.

Tooling Ball

This type of standoff has a steel tooling ball at one end to improve movement and flexibility when positioning and aligning components. This tooling ball design is why this standoff is called a tooling ball, ball-end, and ball knob standoff. The tooling ball at the end can be interchanged to accommodate applications that require a different ball size. Because of their versatility, tooling ball standoffs are commonly used in fixturing and clamping applications.

How to Choose the Best Standoff for Your Needs

Standoffs come in various sizes and types—knowing which is best for you requires an application evaluation.

Size & Shape

First, you need to understand what shape and size you need. Standoffs can come in round, hexagonal, and square varieties. The average diameter of standoffs is a quarter of an inch, but other sizes are also available. There are also different lengths, ranging from a quarter of an inch to two inches. The size will be determined by your application’s spacing requirements (how far do the components need to be separated?)

Thread Type

Next, you need to determine the thread type. Female-female types (rounded and tooling ball) have full or partial threading on each end, while male-female types (pin, rotating, spring-loaded, and tapered) feature internal female threads on one end and external male threads on the other. External threads can vary in size, so you’ll need to know what size you need. Most standoffs can be manufactured with customizable threads for specific applications.

Material

Standoffs can be manufactured from steel, aluminum, brass, plastic, and other materials. The material you need will also be based on application requirements. Consider factors like corrosion resistance, electrical conductivity, vibration resistance, strength, and insulation.

Load Capacity

Understand the weight restrictions of the standoff you are considering. Is it enough to support the components that need to be separated?

Frequently Asked Questions (FAQ)

The weight limitations for any standoff will be determined by the material it’s made from, its size, and how it’s mounted. Bigger standoffs will have higher load capacities, and steel standoffs will have higher load capacities than plastic or nylon.

Pin, rotating, rounded, and tapered are best suited for light-duty applications, while spring-loaded and tooling balls are better options for heavy-duty.

Furthermore, there may be customized standoffs, like rotating pins or spring-loaded tapered pins, with unique load capacities. You will need to check the product page or contact the manufacturer to better understand the load capacity of the standoff you’re interested in purchasing.

What Is the Difference Between Spacers & Standoffs?

Spacers and standoffs are generally used interchangeably. However, there is one minor difference. Standoffs are almost always threaded, allowing them to be screwed in place, while spacers are generally not threaded, though they do allow for a bolt to be inserted.

Get Help From Rayco

For over 43 years, Rayco Fixture has provided quality, American-made products to numerous businesses in many industries. Regardless of the application, we’re dedicated to creating quality fixtures you can trust.

If you have questions about standoffs or need help selecting or customizing one, our team is ready to help. We can handle high-volume orders with care and efficiency and will work with you throughout the customization process to ensure we meet and exceed your expectations.

Contact us today to get started.