Rayco Fixture is heading to the 2021 Quality Show in Rosemont, IL from October 26-28! We’re excited to see you all again, and hope you’ll stop by our booth to learn more about what we have to offer! Click below to find our most up-to-date exhibitor information, and stay tuned for information on upcoming discounts!

BLOG

A Guide to 3 Jaw Lathe Chucks

Mechanics and technicians commonly use lathe chucks to hold and rotate workpieces, making it easier to cut, drill, mill, and perform additional work. Tightening the “jaws” of the chuck is what securely tightens and holds the workpiece in place.

There are four types of lathe chucks:

- 3 Jaw: Approximately 80% of lathe chucks are 3 jaw. They are commonly used to hold round or hexagonal workpieces.

- 4 Jaw (Independent): This is another common type of lathe chuck because it is extremely versatile; it can hold square, rectangular, and irregularly shaped components.

- 4 Jaw (Self-Centering): Self-centering 4 jaw chucks are similar to independent ones, except they have a restricted range of use. They are usually reserved for square stock that needs to be processed quickly.

- 6 Jaw Self-Centering: This lathe chuck creates balanced pressure around the entire circumference of the workpiece to reduce the risk of distortion. 6 jaw chucks are most commonly used for applications that require high precision.

In this blog post, we’ll primarily focus on 3 jaw lathe chucks because they are the ones most commonly used in manufacturing processes.

What Are 3 Jaw Lathe Chucks?

A 3 jaw chuck is a versatile clamping device commonly used in metal, wood, or plastic turning operations on a lathe machine, as well as CNC milling and drill pressing operations.

Machine operators use them by mounting them on the machine (lathe, CNC mill, etc.) and then using the “jaw” to securely clamp the workpiece to the machine. As a clamping device, it provides a stable force that allows accurate and safe turning and cutting on various components that are normally difficult to machine. 3 jaw chucks are particularly useful for round or hexagonal workpieces that require fast and accurate centering or for handling irregular workpieces.

What Are Self-Centering 3 Jaw Lathe Chucks?

3 jaw lathe chucks are self-centering, meaning it has a double-jaw construction; one set of jaws can be adjusted to the internal diameter of a hollow workpiece while the other is used to clamp around the exterior of an object.

The double-jaw design not only offers two-sided support but also increases the range of workpiece diameter that is acceptable with a single chuck. The scroll plate tooth design limits the precision of a 3 jaw chuck compared to a 4 jaw independent alternative.

Benefits

- Cost: 3 jaw chucks are generally less expensive than 4 jaw alternatives.

- Effective Design: The 120-degree, asymmetrical spacing of the jaws in a 3 jaw chuck can actually provide a stronger grip on some workpieces when compared to the 90-degree spacing in a 4 jaw chuck.

- Versatile: As previously mentioned, a 3 jaw chuck is versatile because it can hold round, hexagonal, and irregularly shaped workpieces without having to switch to a different chuck. The versatility of a 3 jaw chuck makes it ideal for facilities that machine a wide variety of components.

- Easy to Center: This type of chuck is designed to self-center the workpiece quickly and accurately, saving time and effort during machining.

Differences Between 3 & 4 Jaw Chucks

There are several primary differences between 3 and 4 jaw chucks:

Use Cases

First, a chuck with 3 jaws is ideal for hexagonal cross-sections and circular items, while a 4 jaw chuck offers better grip performance when handling octagon and square blocks.

Design

A 4 jaw chuck offers independent jaw movement, while a 3 jaw doesn’t. This increases the diversity of available cuts and also requires the operator to accurately center each workpiece.

Setting Speed

The self-centering nature of a 3 jaw makes it a natural option for fast-paced setting and processing. Because a 4 jaw chuck is independent, it slows down processing speeds because the operator must stop to center each workpiece.

Accuracy

Although accuracy will vary based on the centering technique, a 3 jaw chuck is reliably accurate to around 0.010, while a 4 jaw chuck can be accurate between 0 and 0.001.

Number of Wrench Holes

A 4 jaw chuck has four separate holds that can be used to adjust the jaws, while a 3 jaw only has one hole for tightening and releasing the workpiece.

Weight of Workpieces

A 4 jaw chuck is better suited for heavy stock, and a 3 jaw is ideal for moderate-to-light applications.

Cut Depth

4 jaw chucks generally can achieve a higher cut depth.

Selecting a 3 Jaw Chuck

First, ensure the workpiece configuration is a good fit—you need round or hexagonal pieces without a thin wall.

The next consideration is ensuring your lathe or other industrial machines can manage the high speeds and powerful clamp forces needed for large, through-hole operations. In these operations, the larger and heavier 3 jaw chuck is optimal.

Rayco’s 3 Jaw Chucks

Rayco Fixture offers several 3 jaw chucks that can be used for CMM fixturing:

- R20-CJ3:

- Thread Type: ¼-20

- Weight: 4 Pounds

- Dimensions: 7 (W) x 5 (H) Inches

- Pricing: $365

- R6-CJ3:

- Thread Type: M6

- Weight: 4 Pounds

- Dimensions: 177.8 (W) x 127 (H) Millimeters

- Pricing: $365

- R8-CJ3:

- Thread Type: M8

- Weight: 4 Pounds

- Dimensions: 177.8 (W) x 127 (H) Millimeters

- Pricing: $365

FAQ

What Are the Maintenance Requirements?

3 jaw lathe chucks are fairly easy to maintain. All you need to do is regularly clean, lubricate, and inspect them.

- Cleaning: Remove dust, debris, and other buildup on the lathe. Use a soft-bristled brush or cloth. Do not use any abrasive cleaners.

- Lubrication: Use a small amount of oil or grease (the manufacturer will recommend a lubricant type) to the chuck’s moving parts.

- Inspection: Look for common signs of wear and tear, including cracks and chips, before and after operation.

- Jaw Alignment: Also ensure that the jaws are properly aligned—if they’re misaligned, it can cause inaccurate machining, which will cause further damage to the chuck.

- Storage: Store your chucks in a clean and dry location to help prevent rust and corrosion. It’s also best to cover them to prevent dust buildup.

What Type of Lubrication Is Needed?

Manual lubrication is recommended. The lubricant type will vary based on the manufacturer. As a general rule, you will most likely be fine using a light oil or grease. The type of lubricant you choose should have good adhesion properties and not attract dust or debris. When applying lubrication, don’t overdo it. Just use a small amount—too much lubricant can impact the chuck’s accuracy and potentially cause damage to the workpiece and/or chuck.

Have Questions? Contact Rayco!

Rayco Fixture has been a trusted manufacturer of CMM fixture kits and components for over four decades. We sell a wide range of clamping and holding devices and can even help you design custom fixture plates. Contact us today if you need help selecting the best lathe chuck for your application or have questions about our products and capabilities.

Guide to Spring Holding Devices

What are spring holding devices and how can they improve your existing process? Find out more in this article by Rayco Fixture.

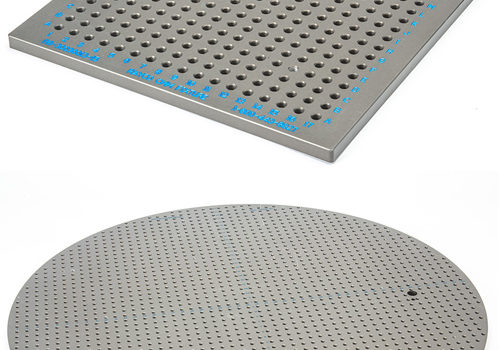

CMM Fixture Plates & Components

What are CMM fixture plates and why are they needed in quality control processes? Learn this and more in this comprehensive guide.